PACTEC REVOLUTIONIZES VACUUM TRUCK PROCESS WITH CUSTOM BAGS

Our environmental service company customers all expressed the same frustration – high clean out

costs. PacTec, Inc. engineers went to work to develop a bag and process-for-use to remedy their

woes.

BACKGROUND

By nature, the vacuum process is a messy job. Pond sludges and dusty wastes both presented similar

problems to the environmental service companies utilizing vacuum trucks for cleanup – difficulty

cleaning the box out. Once ponds are vacuumed out and the sludges emptied from the vacuum box,

their workers were left with a difficult cleanup job removing the remaining residue. They were

experiencing downtime on projects which drove costs up, thus endangering their ability to win

future bids. Other companies were experiencing problems leaving dust clouds in their wake when

dumping lightweight at landfills.

OUTCOME

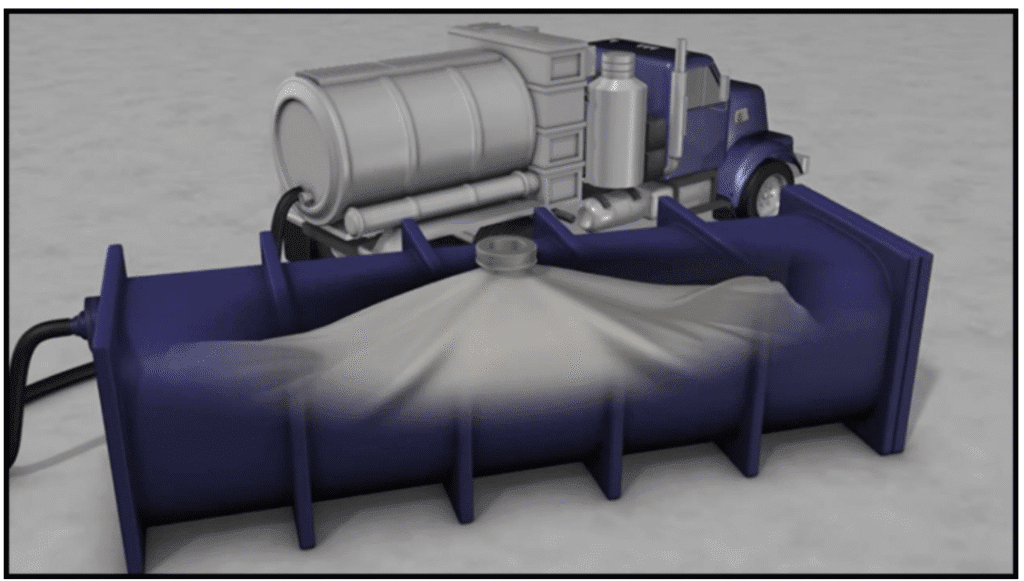

The Engineering and Research & Development teams at PacTec, Inc. set out to design a solution for

this, conceptually similar to the way a home vacuum cleaner operates. Much like those have bags to

contain the particulates it captures, we reconfigured our TransPac product to function in the same

way, and developed a process for companies to easily use them. That process can be viewed here.

The TransPac prevents sludges from sticking to your vacuum box and ensures that your box does not

leak. It can also prevent “dust clouds” at the landfill when hauling a dusty, powdery waste. The

TransPac can also be used in roll-off or end-dump containers for many waste streams including high

heat waste.

HIGHLIGHTS

- Reduces cleanout costs

- Easy to use and adapt for most uses

- Affordable way to prevent leaks and dust clouds